The Consortium of On-Board Optics (COBO) is progressing with its work to create specifications for co-packaged optics.

The decision to address co-packaged optics by an organisation established to promote on-board optics reflects the significant industry interest co-packaged optics has gained in the last year.

So says Brad Booth, director, leading edge architecture pathfinding team in Azure hardware systems and infrastructure at Microsoft.

Source: COBO

Source: COBO

The COBO work also complements that of the OIF which has set up its own co-packaged optics framework.

“We have a different collection of members [to the OIF],” says Booth. “Our members are very strong on optical connectivity and materials whereas the OIF is known for its electrical interface work and module activities like 400ZR.”

Booth has no concerns that the two groups’ specification work will overlap. The organisations have a history of working together and the head of each co-packaged optics activity is active in both COBO and the OIF.

Specification work

The COBO working group’s first output will be a white paper addressing co-packaged optics’ connectivity and thermal issues. This will be followed by specifications required in these areas.

Booth says much work will be needed to specify co-packaged optics. Booth can list 12 possible specification items that would be needed to create an interoperable ecosystem.

Some of the specifications already exist. “A lot of people are referencing the OIF CEI-112G XSR specification for the electrical interface,” says Booth. “There are also discussions about a second-generation interface which may be a different, more analogue-style interface, what some call direct-drive.”

Brad Booth

Brad Booth

The OIF has taken on the electrical-mechanical work given it is critical for the optical chiplet definition.

COBO has initiated external laser source specification work due to the close ties to the optical fibre and connectors work already being done by COBO's CPO working group.

“We will be having a lot of conversations with our colleagues in the OIF, and with the IEEE regarding their Ethernet specification work,” says Booth.

That is because co-packaged optics increase significantly the bandwidth-density using an optical chiplet compared to what is possible with an optical module.

“People are working on vertically integrated solutions but that doesn’t help the end-user because we may want different optics than what they make, or a different switch engine,” says Booth.

The goal is for co-packaged optics to have the same openness that exists today when building systems, having a multi-vendor choice regarding the chips and optics used.

The co-packaged work will also specify optical connectivity and external lasers issues.

Interoperable co-packaged optics need not use external lasers, says Booth. But when using built-in lasers, it is not a critical concern to create a specification since there is no exposed connector.

With an external laser, however, a fibre goes from the laser source to inside the package and how that is done must be specified.

Applications

Co-packaged optics is expected to be adopted in such applications as Ethernet switches, Ethernet network interface cards (NICs), Infiniband switches and compute fabrics for artificial intelligence and supercomputing.

Ethernet switches are the main focus due to the industry facing a bandwidth-density issue associated with switch silicon.

“That is the first foray, the beachhead, for figuring out how to do co-packaged optics but it’s not the endpoint,” says Booth.

On-board optics

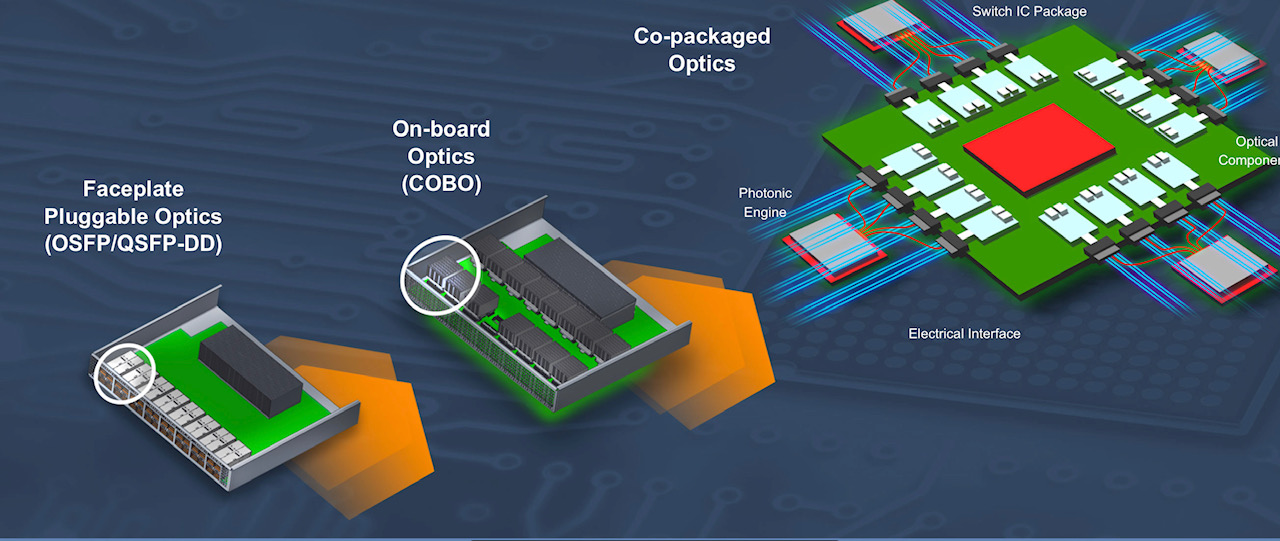

COBO was created to make on-board optics interoperable. Here, optics is embedded on a board to be closer to the ASIC, shortening the printed circuit board’s (PCB) electrical traces and freeing the front panel from pluggables.

COBO was backed by Microsoft and was promoted as an important intermediate step in the evolution from pluggable modules to co-packaged optics.

“The focus has moved more towards co-packaged optics,” admits Booth. “Although what is interesting is that Facebook did an on-board optics platform, and Microsoft did, and we got learnings from that.”

Facebook’s on-board optics is sourced from a company and is not COBO-complaint.

Microsoft could also have chosen a proprietary solution but it wanted to avoid being dependent on a single-source solution, given its unit requirements would be much greater.

Booth says companies are starting to build and deploy on-board optics partly because it is a valuable learning curve before moving to co-packaged optics, ‘on-board optics on steroids’ as Booth calls it.

For Microsoft, developing an on-board optics proof-of-concept platform provided valuable knowledge that it is now taking into co-packaged optics. “The beauty of creating the on-board optics specification is at least we have a standardised way to approach this.”

Once co-packaged optics gets adopted, people may think on-board optics will no longer be needed, he says. But co-packaged optics doesn’t solve everything. “It doesn’t do long-haul, or metro data centre interconnect links that Microsoft uses, such as 400ZR,” he says.

Given the higher speed of the electrical interfaces used by next-generation coherent interfaces, the trace lengths on the PCB will shrink. On-board optics will then become more attractive than faceplate optics.

In contrast, with co-packaged optics, the optics is embedded. A different co-packaged optics is needed for metro links than for use within the data centre. “Is there value in that?” says Booth. “That is a question that still needs to be answered.”

The work for interoperable on-board optics is now done. Pluggable modules such as the QSFP-DD and OSFP may support 400 gigabit and soon 800-gigabit but, with each speed hike, power and signal integrity issues worsen.

For example, 400-gigabit QSFP-DDs consume 10-14W but at 800 gigabit the power approaches 20W. That equates to a module case temperature of 70oC. That makes working and replacing pluggables an issue.

“If we had faceplate pluggables and the only other option was co-packeged optics and we had to wait for that to solve what pluggables can’t do, we as an industry would be in serious trouble,” he says.

Microsoft had designs based on COBO optics but the Azure networking team decided to use QSFP-DD for 400-gigabit, primarily because of 400ZR.

“Does that mean we have backed away from on-board optics?” says Booth. “If I talk to my sourcing team, its position is no."